INNOVATIONS

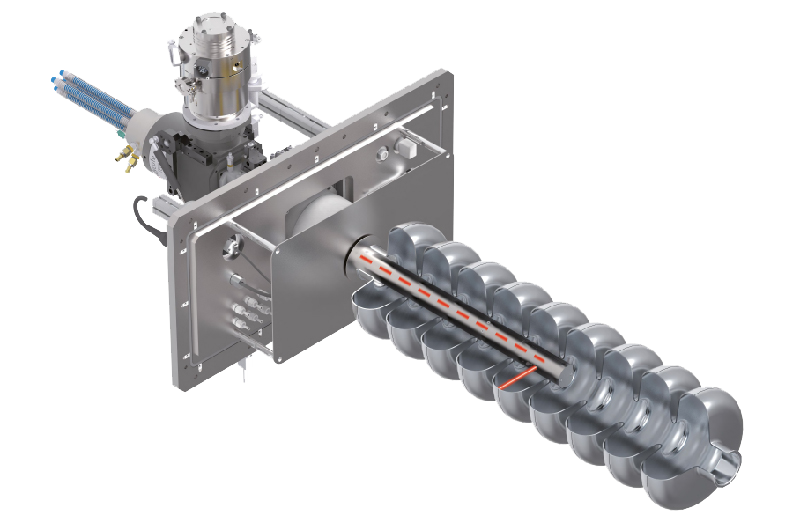

TechBend®

Applications

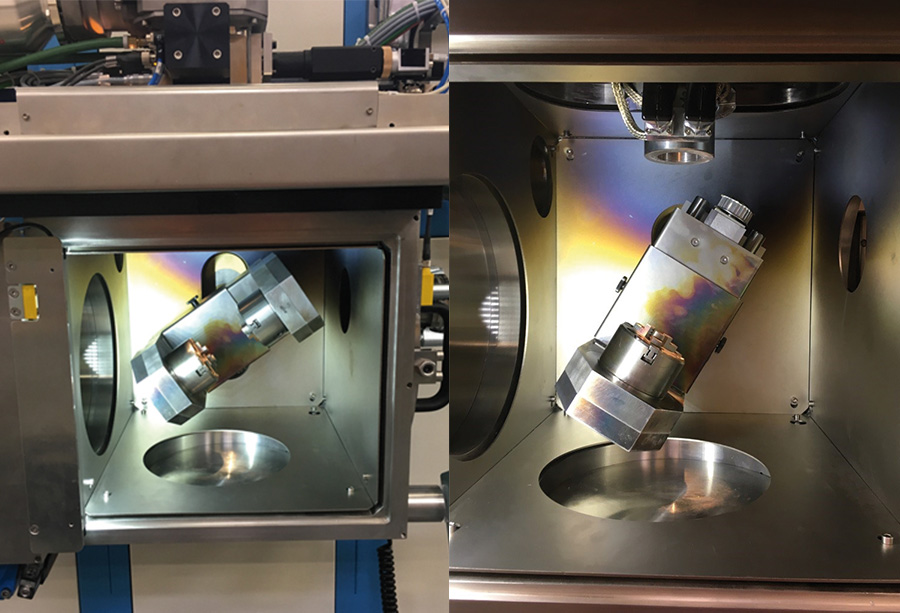

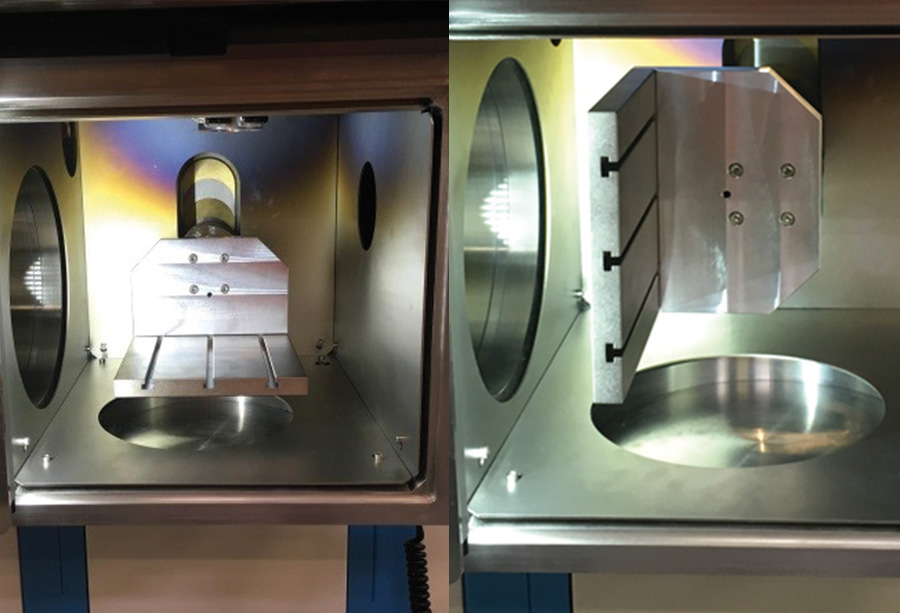

Niobium cavities

Copper cavities

Aluminium casing

Advantages

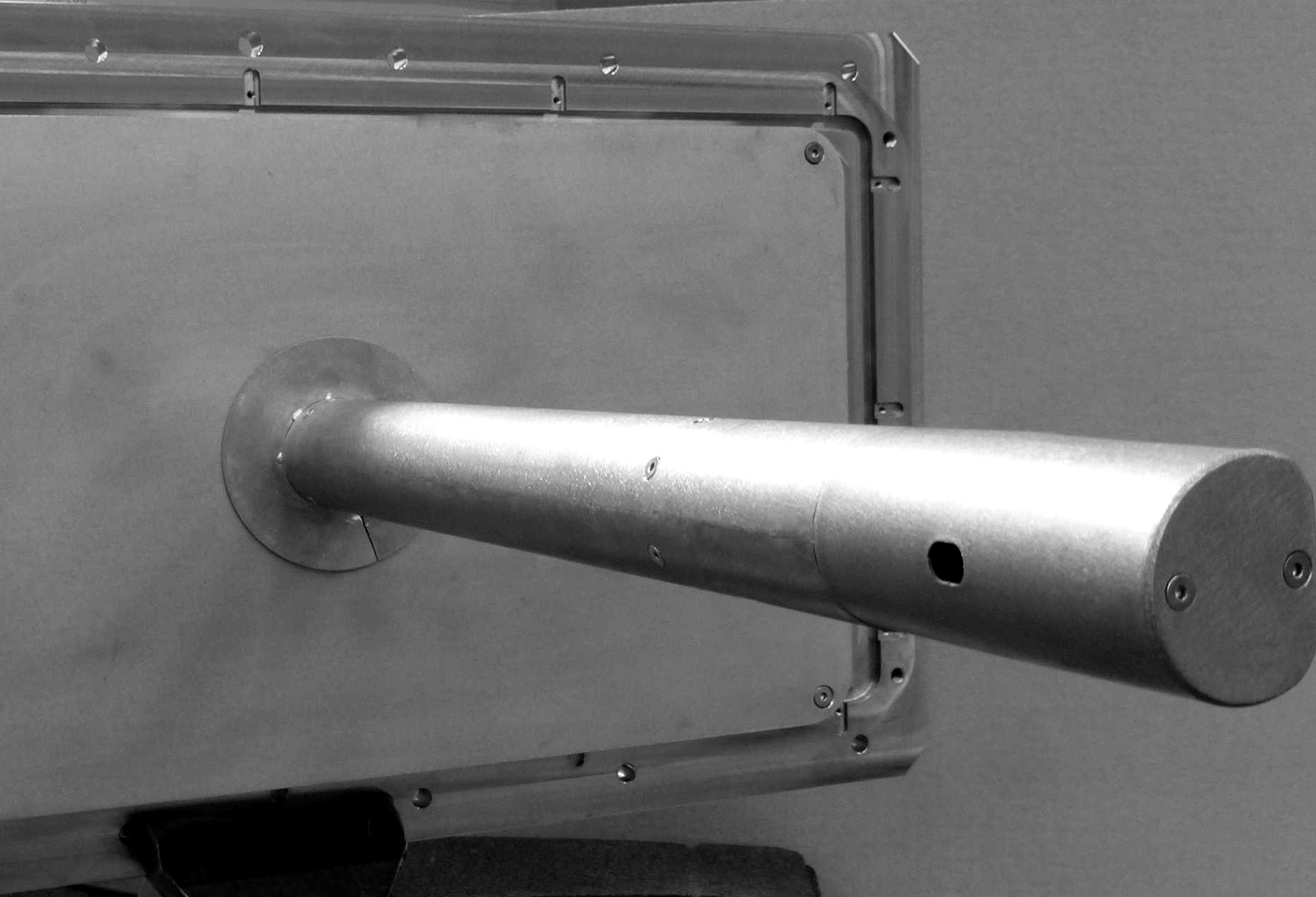

Extremely smooth weld seam on the inside surface of the cavity without needing any extra machining

Welding of unreachable seam

Complete inside welding with/without smoothing

Inside smoothing pass for outside welded parts

Different diameters are possible for welding of iris and equator from the inside (up to 1.3GHz cavity included).

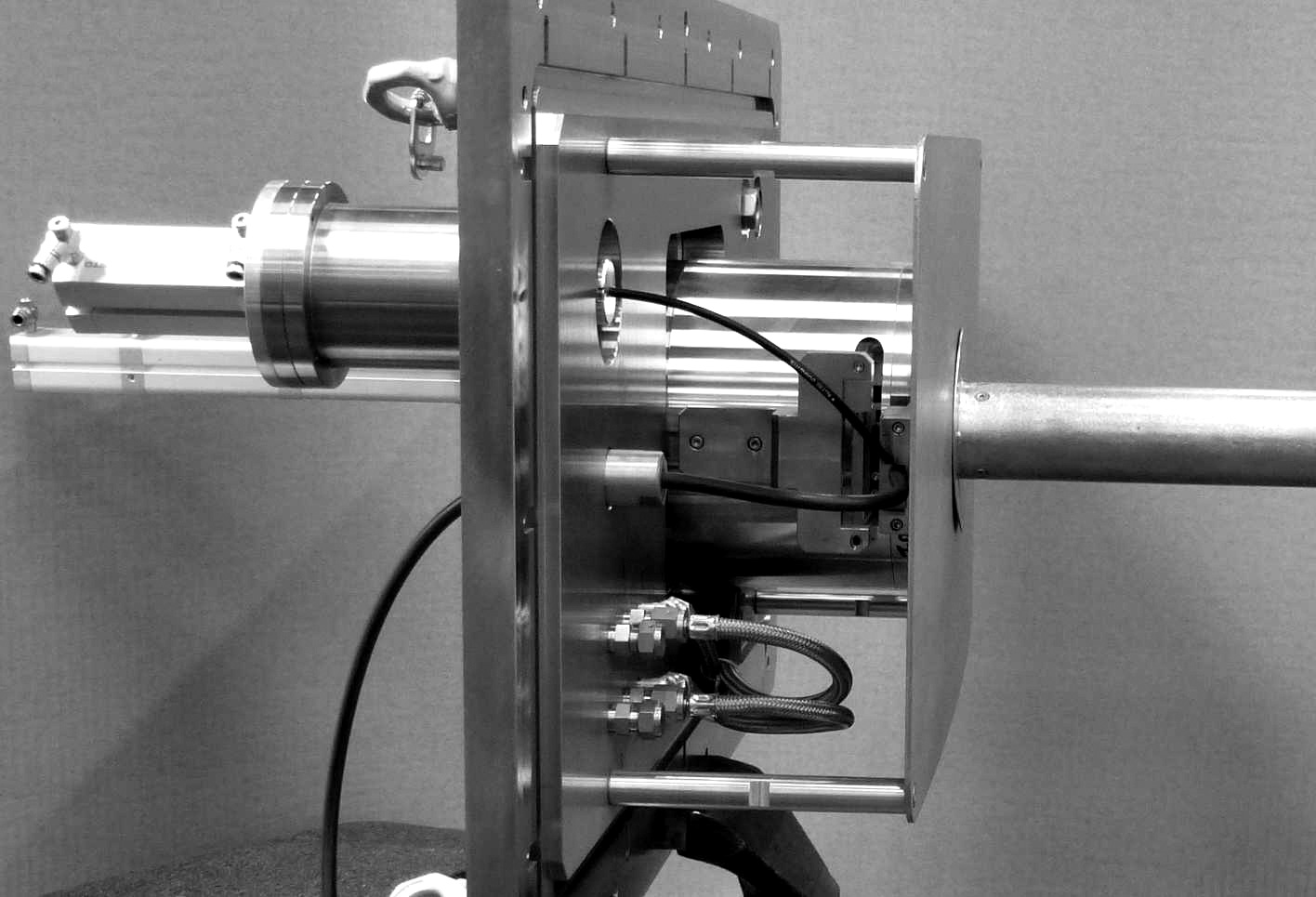

Vacuum level

=< 1.10-2 mbar

Electron gun

from 35 to 60 kV

Beam adjustment, centering

and welding in same vacuum

All models,

Beam adjustement,

centering and welding

in same vacuum

Over-clearance

to the beam

75 MM

Automatic beam centering

on bending system

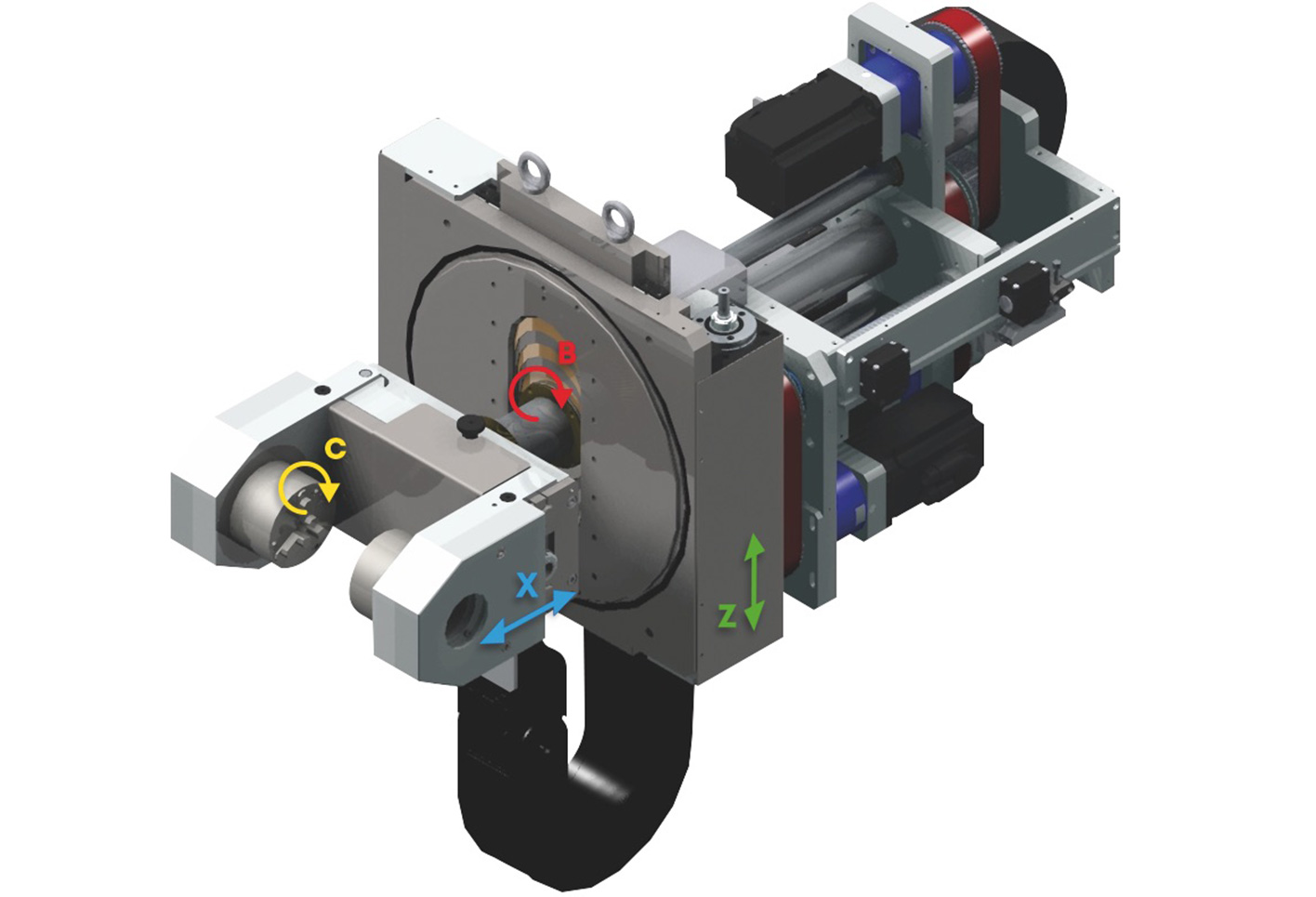

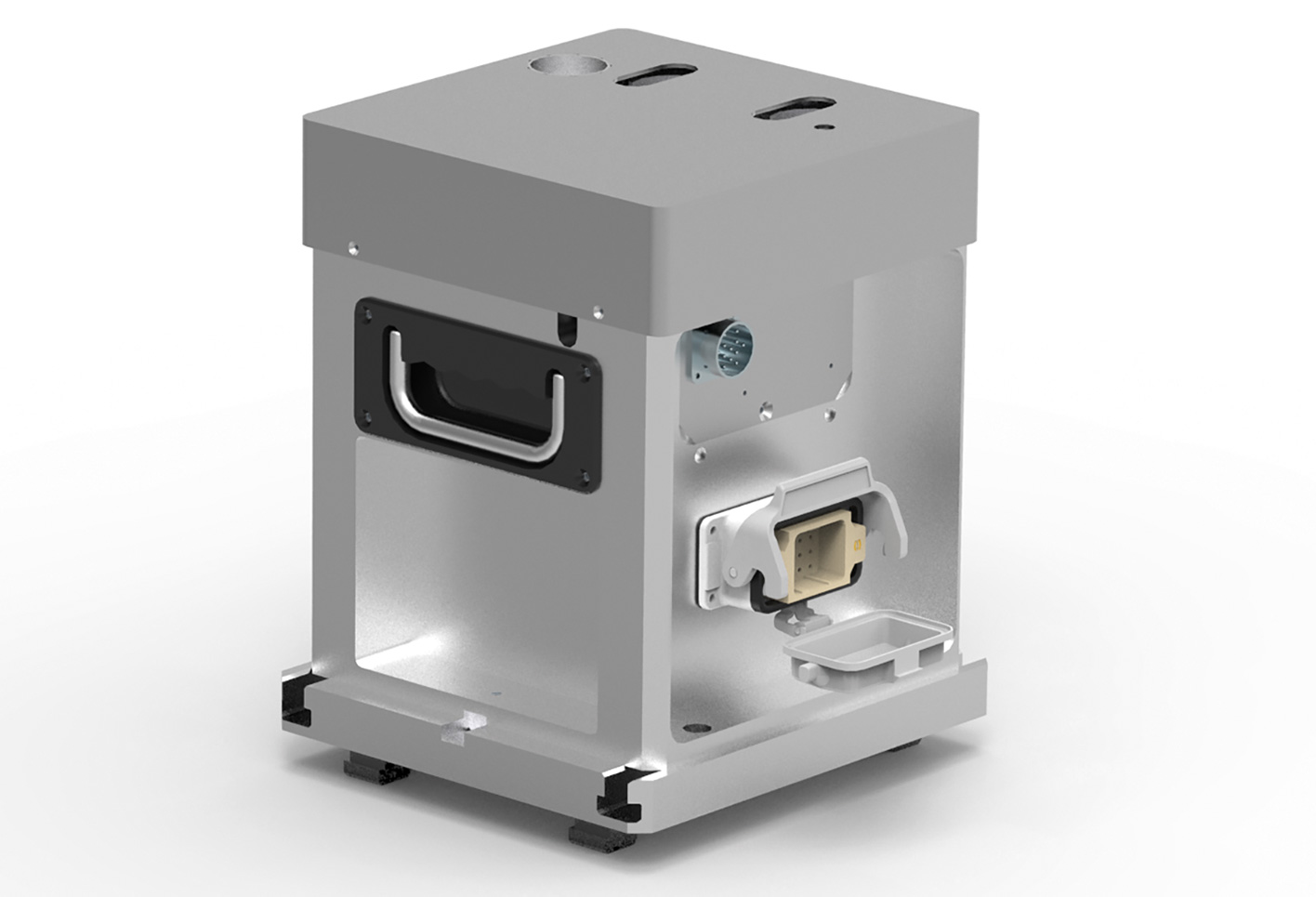

Rotating Chuck

Specificities

Rotation: C axis

Maximum diameter of part: 140 mm

Maximum length between spindles:

140 mm

Tilting: B axis

Adjustable from 0 ° (horizontal axis of rotation)

to ± 90 ° (vertical axis of rotation, spindle up or down)

Height: Z axis

Z axis stroke: 140 mm

Translation: X axis

X axis stroke: 150 mm

Money saved

Not necessary to design complex fixture to weld with an angle from 0° to 90°

Space saved

Optimized design fitting with small chambers down to 500x500x500 mm

Unique and universal device

Rotating system

or table

can be switched easily in less than 10 minutes

Can be installed on

existing machines

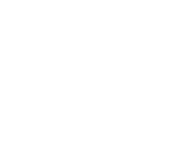

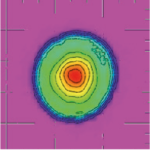

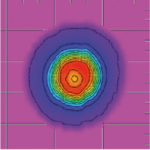

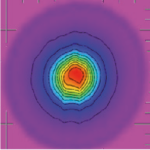

TechScan

BEAM CONTROL

Electron Density Distribution / Wear detection / Geometry control / Human input control

CORRECTION INDICATIONS

Cathode adjustment / Cathode Change / Centering corrections

PRODUCTION CONTROL

Integrity check / Go/Nogo / Quality report / Operator friendly

100% AUTONOMOUS

Dedicated deflection coil /Dedicated power unit / Dedicated PC and software

FOCUS COIL

& ELECTRODES CENTERING

No limit to your imagination

We design and manufacture the machine

that best fits with your welding needs

Feel free to question us.